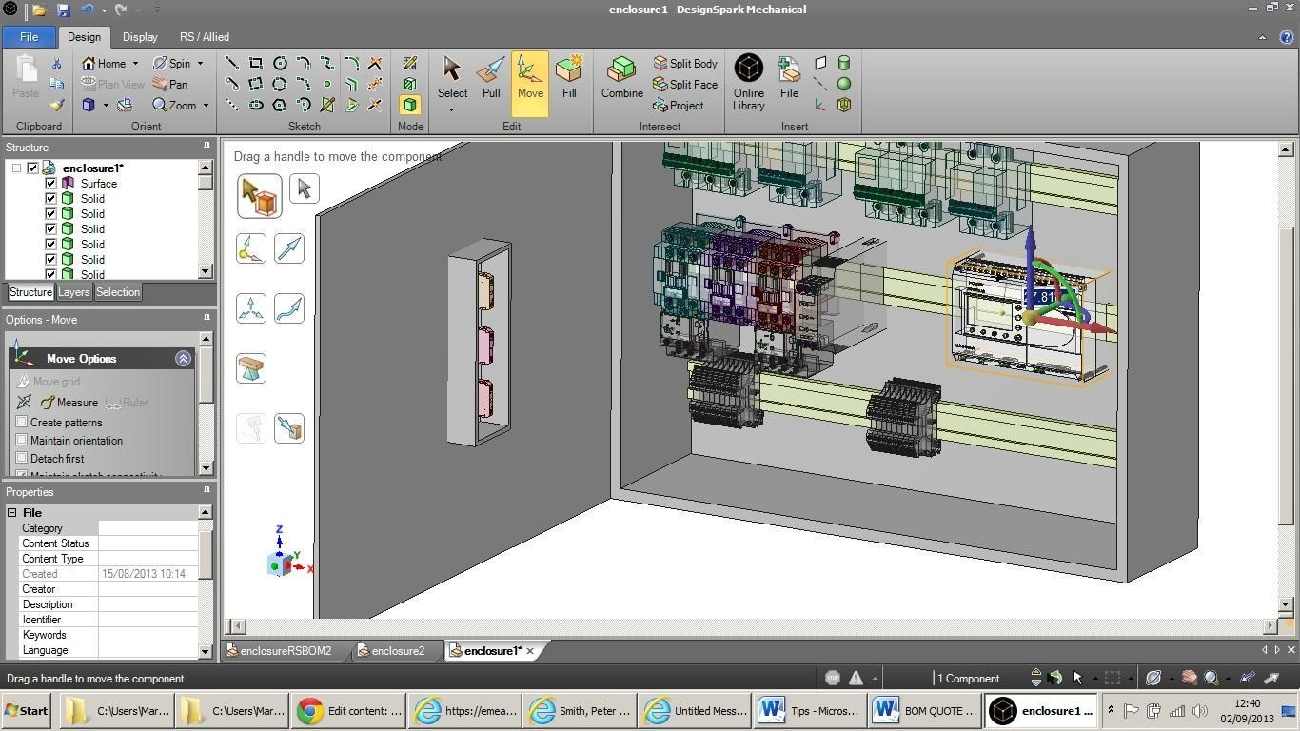

The drawing environment provides a familiar work space for those accustomed to working in 2D. This great module lets you change designs as well as create and modify geometry from within drawing views. This module turns DesignSpark Mechanical into a low-cost 3D design solution, ideal for companies wanting to create fabulous product concepts without having to invest in 3D CAD licenses and training, or for businesses wanting to reduce reliance on contractors for final design creation and manufacturing. With this module you can freely import, modify, and export the industry standard STEP and IGES file formats, allowing you to fully exchange design data with CAD tools such as SolidWorks, Catia, ProEngineer, and AutoCAD. With this in mind, we are introducing optional premium modules that will give those users the advanced capability they require. As it’s popularity continues to grow, we’ve worked with our users to understand what they want in addition to the standard free functionality that would help them take their designs from concept to production-ready. Even though the little knob at the tip of the finial prints solid, it isn't very strong and can break off easily, so be careful.Introducing the NEW DesignSpark Mechanical Add-On ModulesĭesignSpark Mechanical is and always will be free software with continued support and new versions introduced periodically. I printed using ABS with 0.2 mm layers and 40% infill for strength, and of course, I used support material. The finial will need support material when it prints, and after it is removed, the underside of overhanging surfaces will be rough- you'll have to do a little sanding. I chose the first option and printed a small cylinder along with the finials. The first option wastes a small amount of filament, the second can be tricky because plastic can drool out of the nozzle while it is waiting and that will put a blob of plastic on the print every time it starts a new layer. You can print an additional object at least as tall as the finials to give the printer something to do while the tiny finial parts cool between layers, or you can add custom gcode for every layer change that just makes the printer wait for maybe 10-20 seconds to start printing after each layer change.

There are a couple ways to prevent the print quality problems that printing tiny layers can cause. If the nozzle goes back to a small area before it has had a chance to cool, you'll end up with a blob. Notice that when the printer gets to the top of the print, the area on each finial will be very small and will complete printing quickly. I printed four of these at the same time using ABS.

0 kommentar(er)

0 kommentar(er)